Making lightweight miniature 5G mmWave components with layers of material.

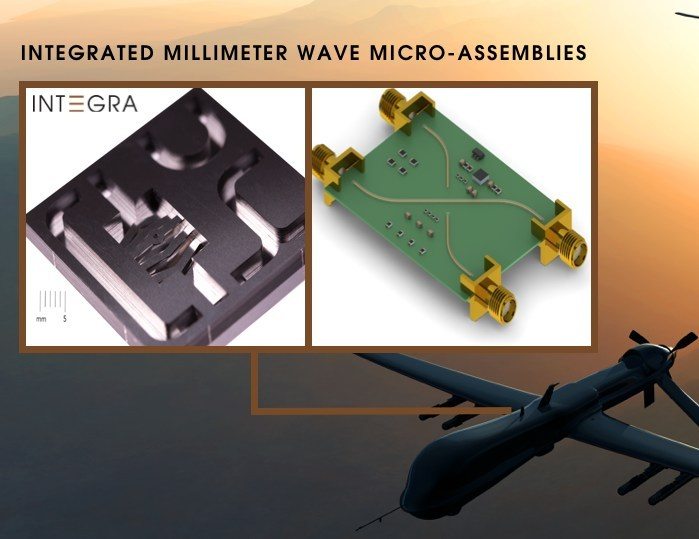

Industrial component startup Integra Devices is using a process for making very small components and substrates used in 5G technology. The company’s AMALGA process produces miniature, low-cost mmWave components. Users can manufacture complex 3D microstructures in laminates such as package substrates and printed circuit boards.

The process laminates layers of material, such as foils and films, to create 3D structures. The process also fabricates hollow, metal waveguide and coaxial structures inside and on top of electronic substrates. The company says filters, diplexers, switches, attenuators, and other components can be integrated within these structures.

The process is either custom or used in Integra Devices products. For example, Integra’s Neuron series: DC – 12 GHz SMT micro-relays is 4 x 4 x 2 mm.

3D Waveguide and 3D Coaxial structures embedded inside and on top of electronic substrates (PRNewsfoto/Integra Devices)

The AMALGA process came out of research done at the micro-fabrication labs at the University of California, Irvine, over 15 years. The startup has over $20 million of funding from government agencies. industry players such as DARPA, Samsung, Texas Instruments, and more “fueled this innovation with the intent to change the way micro-devices are built,” says the company’s press release.

The post Making miniature, low-cost mmWave components appeared first on RCR Wireless News.