With the advent of 5G, signaling test at manufacturing is more important than ever

5G, the multi-faceted technology of the coming decade, is designed for use cases that go far beyond smartphones; it will prove to be one of the foundational pillars for many industry verticals. With the aim to improve wireless connections worldwide and provide better user experience, several companies are designing devices with 5G capability ranging from connectivity equipment like customer premises equipment (CPE) and fixed wireless access (FWA) systems to internet of things (IoT) devices like wearables, trackers, sensors and mission critical devices like autonomous vehicles, virtual reality (VR) headsets for assisting surgeries and much more.

Such a diverse and novel range of cellular-capable devices will have remarkably different usage models, device designs and performance. Some may be designed to interact and exchange data at lightning-fast speeds with multiple other terminals, as in case of Industry 4.0 where synchronized robots are used at the factory floor for real-time monitoring, or autonomous vehicles where excessive coordination is required between the camera, sensors, GPS and technology subsystems of the car with the base station. In other cases, some devices will enable high-speed audio and video communication as in the case of CPEs, smartphones or hotspots, and some devices will tend to applications demanding reliability, efficiency and longer battery life as in the case of drones, fitness trackers and smart home devices.

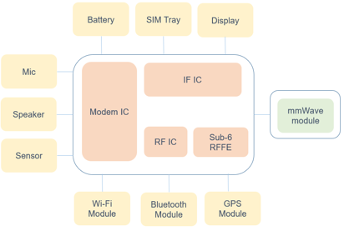

As exciting as the use cases may sound, enabling such an extensive feature set in a cellular-capable smart device means several components need to be designed-in, such as the battery, processor, modem, RF/IF subsystem, antenna modules and peripherals like a camera, audio, GPS and much more. This underscores the importance of testing to ensure each of the components are working together to deliver the desired capability and performance when deployed in the real world.

Simplified block diagram of a cellular device. Image: LitePoint

Although cellular testing is not a new requirement, testing such an unfamiliar set of devices may be challenging considering:

- The OEMs and their manufacturing lines are set up to test standard devices like smartphones, tablets, hotspots, or other IoT devices. Hence, to incorporate testing across new form factors, the test setup and fixtures would need to be updated.

- Secondly, many of these devices have never been tested from a cellular perspective, which implies newer test cases would need to be added to verify state-of-the art features within each test area – research and development (R&D), design validation test (DVT), sampling, production, or service centers.

- Further, many of these devices will be equipped to support advanced functionalities like eSIM, multi-SIM, exceptionally high throughput, extreme mobility, co-existence with other connectivity technologies, voice over NR and video over NR, which would make real-world scenario testing all the more necessary pre-deployment.

- With more diverse and growing 5G use cases around the world, the demand for 5G modules is increasing. According to the “5G Digital World – Built on Chips” report published by Omdia, by 2025 more than 100 million 5G IoT modules are expected to be shipped, suggesting a rise in the market for 5G module based IoT devices. This prompts the need to perform cellular signaling test not just at R&D but even more so at manufacturing.

- Last but not the least, 5G technology supports flexible frequency range of use, diverse bandwidths, sub carrier spacings, modulation schemes, etc. which necessitates adequate testing. In addition, at millimeter waves, owing to the path loss associated with the over the air (OTA) test methodology, careful consideration has to be made when choosing the chamber and related accessories to accurately verify the performance of the device with a given form factor and antenna configuration.

All of this requires rethinking the traditional test methodologies to ensure quality product and performance testing.

Signaling vs Non-Signaling Testing

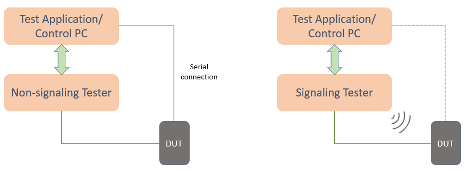

Before we delve deeper into the different types of signaling tests that must be performed across 5G devices, let’s differentiate between the two cellular testing techniques – signaling and non-signaling.

Non-signaling testing is conducted at nearly every stage of product development, although it is highly targeted and optimized for use at manufacturing. The technique makes use of an RF signal generator and analyzer to predominantly focus on calibration and verification of device RF transmitter and receiver performance. This type of testing is performed in non-call processing mode and makes use of chipset-specific test mode to measure pre-defined transmission patterns, thereby minimizing test time and improving cost of test.

Simplified block diagram of signaling vs non-signaling test. Image: LitePoint

On the other hand, signaling testing is extensively used during product development stages like R&D and DVT and uses a base station emulator to establish an end-to-end user plane call with the device under test (DUT). This approach is extended, as it uses a combination of control plane signaling and user plane traffic to measure the true performance of the DUT under realistic test conditions, but aids in verifying each layer of the protocol stack to perform comprehensive device testing.

Although non-signaling testing is specialized and fast, it’s exclusively geared towards verifying the standalone performance of the device transceiver, thus factoring out the impact of live network conditions and other components within the hardware on the overall functionality of the finished product.

Importance of 5G Signaling Test at End-of-Line (EOL) for Quality Assurance

When building products with a chip-on-board (COB) design, protocol and functional testing are integral parts of the product design and development stages to ensure the device goes through extensive feature testing and software regression prior to manufacturing.

However, the test dynamics change when building products using third-party cellular module/RF subsystem/antenna modules as, even if the modules sourced are certified, it does not guarantee the final product will function as desired in the field. Once packaged together the components can notably impact each other and the overall behavior of the product in real world network configurations. The table below highlights some of the common issues seen in the field:

| Functional Issues | Potential Root Cause |

| SIM connectivity issue or call registration failures | Could result from software/ firmware bugs. |

| Low throughput | May result from poor transceiver performance reflected as frequency errors or degraded error vector magnitude (EVM). |

| Higher block error rate (BLER) | Owing to poor receiver sensitivity. |

| Mobility failure | Due to degraded sensitivity, signal demodulation/ modulation issues. |

| Radio link failure | Owing to frequency or time offset, poor signal to noise ratio (SNR). |

| Choppy voice and video quality | Especially at cell edge, due to compressed low-noise amplifier (LNA) gains and non-linearity resulting in degraded sensitivity. |

| Dropped calls | Due to improper antenna installation or impedance mismatch. Poor isolation between Tx and Rx paths causing desensitization. |

| Poor reception/ slow downloads | In-device coexistence issues between Wi-Fi/Bluetooth/cellular modules causing interference, thus decreasing receiver sensitivity. Carrier leakage from a neighboring device transmitting at higher Tx power. |

| Short battery life | Resulting from high transmit output power even when close to the base station or when transmitting low data throughput. |

This interconnectedness and non-mutual exclusivity between components strongly marks the relevance and need for signaling test in the pre-production and production stages to test the product in its entirety to validate:

- Basic device registration and call procedures ensuring end-to-end product functionality, as the hardware components and system firmware could potentially impact the DUT’s wireless performance.

- Antenna performance, as final product casing, implementation and tuning errors could cause signal loss and impact the antenna radiation pattern leading to communication failures.

- RF performance, to ensure signal quality is not heavily degraded under realistic channel conditions with acceptable levels of signal transmission and reception as defined by 3GPP and other certification bodies.

- Data throughput, as in real life conditions the device must be able to sustain and handle varied user plane traffic and quality of service (QoS) requirements.

- Real-world user experience features, like voice, SMS, browsing, file transfer, handover, redirection, etc.

- Advanced functional features, like embedded SIM (eSIM), multi-SIM testing for immediate connectivity.

As a next generation technology, 5G offers a lot more flexibility and an extensive feature set as compared to the legacy cellular technologies and signaling testing can help ensure holistic product quality across different deployment models. However, having outlined the importance of quality test, it becomes equally important to choose a signaling test solution that not only supports versatile functional tests but also improves parallel test efficiencies. Consensus amongst the production test team and the test vendor can help the vendors develop tools that support quick Tx-Rx diagnostic tests and support automated testing thus reducing time to market and controlling the cost of test.

The post Importance of Real-World Scenario Testing for 5G Products (Reader Forum) appeared first on RCR Wireless News.